EN standards define 5 “Types” of application-based chemical protective clothing. But what do they mean and how do they differ from North American OSHA protection levels?

For a global business looking to standardize PPE in every regional base the need to meet multiple local standards and conventions is a challenge. When managing hazardous chemicals in the workplace an understanding of the differences between regions can be useful. This blog aims to explain the chemical protective clothing Types defined by EN standards, the OSHA Protection Level guidance used in North America, and to show where they are different or similar.

EN Standards for Types of Protective Clothing

The system launched in the European Economic Community in 1995 aimed to improve the levels of protection against workplace hazards by introducing a legal requirement that all PPE should meet minimum performance requirements. This was achieved through the publication of standards for PPE performance, with compulsory compliance being independently audited and approved by appointed “Notified Bodies”, and indicated on PPE labels by the now well-known CE mark.

|

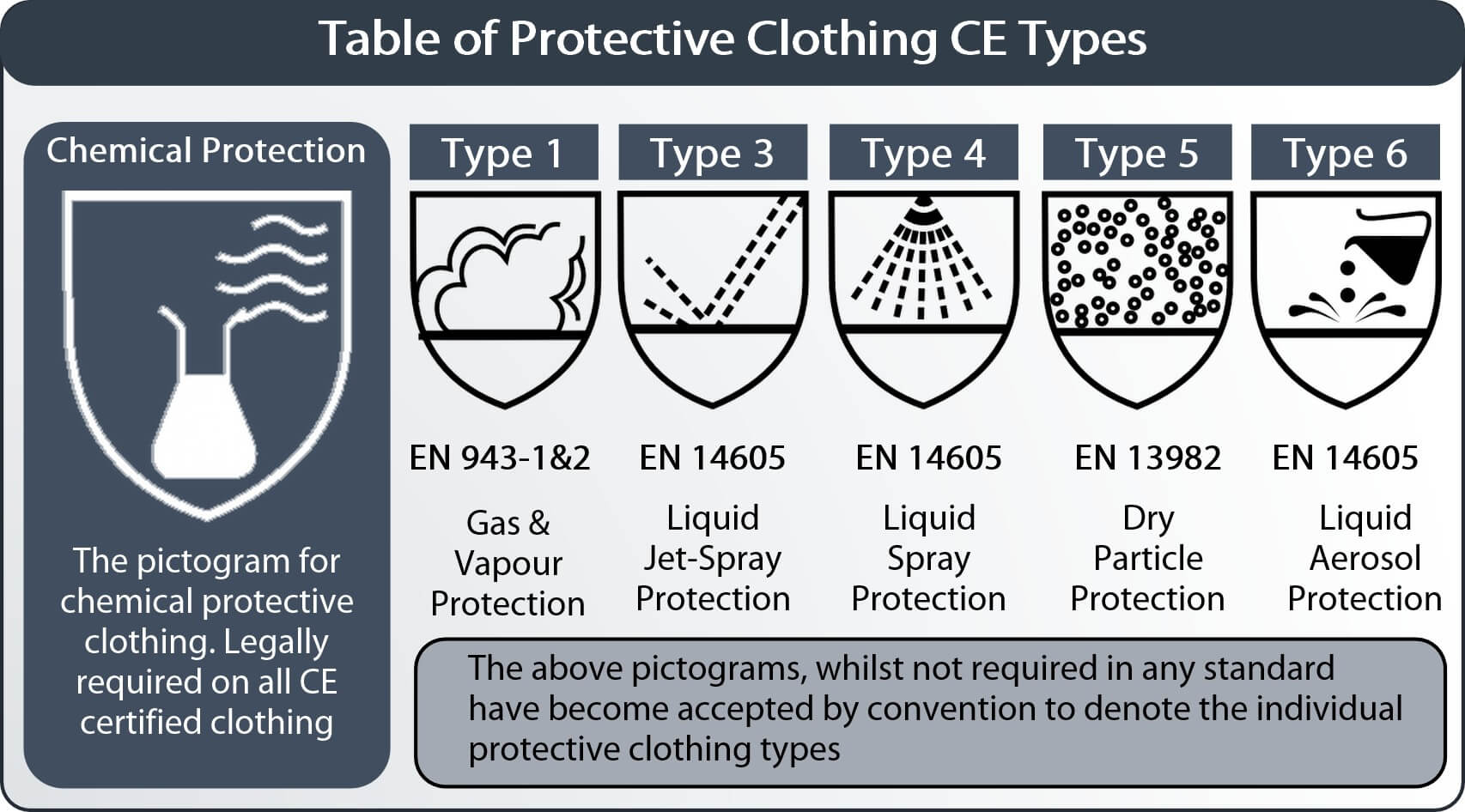

For chemical protective clothing several CE standards define performance requirements according to the hazard; it’s state: liquid, dust, or gas, and in the case of liquids: light aerosol, liquid, or jet sprays. These define 5 “Types” of clothing according to level and type of protection provided.

A Notified Body is an organization appointed by an EU member government to audit specific types of PPE according to relevant standards and to issue a CE certificate based on that audit. For Safety Managers it is useful to know that certification and all required testing is conducted independently of the manufacturer. |

Meanwhile in North America no such mandatory or optional standards exist for chemical protective clothing. However, OSHA, the Occupational Safety & Health Administration, the government agency charged with “ensuring safe and healthful conditions for workers” has issued four “Protection Levels” as guidance for choosing PPE for protection against hazardous materials in the workplace.

The PPE or the Hazard? An Important Difference

A key difference between the approaches of Europe and America is that whilst European chemical suit standards focus product – in this case clothing that protects the skin of the wearer, with respiratory and ingestion hazards dealt with by other standards, the protection levels in America address whole body protection including, and treating as primary, protection against respiratory hazards. Thus, the OSHA levels address all the required PPE, considering respiratory protection as paramount, whilst the EN standards have different standards for different PPE.

(This distinction between product and hazard is also seen in other protection types. For example, the EN standard for fire fighters clothing, EN 469, defines requirements only for clothing, with other fire-fighters PPE being addressed by separate standards. In North America however, the equivalent NFPA 1971 standard considers requirements not only for clothing but also for helmets, gloves, boots and so on. It’s title refers to “…protective ensembles…” for fire-fighters rather than “fire-fighters’ clothing”. |

This means direct comparison of the EN standards and OSHA protection levels is difficult; there are no direct equivalents. However, below is an analysis of both and a summary of how they compare.

EN Standards for Chemical Resistant Protective Clothing

In EN standards all PPE is classified as follows: –

| Category I | Products designed to protect against minimal hazards |

| Category II | Intermediate products that are neither category I nor III |

| Category III | Products designed to protect against hazards that may cause serious injury or are a threat to life |

The key standards for chemical protective clothing are: –

| Type 6 | EN 13034: Clothing for protection against light aerosol sprays of liquids |

| Type 5 | EN 13982: Clothing for protection against Hazardous Dusts |

| Type 4 | EN 14605: Clothing for protection against liquid (shower-type) sprays |

| Type 3 | EN 14605: Clothing for protection against liquid jet sprays |

| Type 1 | EN 943: Gas-tight Clothing for protection against gases and vapours. (This is sub-divided into parts 1 and 2, with Part 2 being clothing for Emergency Teams and featuring additional requirements) |

Originally there were 6 TYPES, Type 2 being included in EN 943 and being air-fed “non-gas tight” clothing. However, this was rarely used and commonly misunderstood, so was withdrawn in the 2015 version of EN 943 |

Garments certified to either one or more of these standards must display the specific pictogram below to indicate “chemical protection” on the label.

However, in addition many manufacturers also use the pictograms shown in the table below to indicate the Type of clothing. Note that these Type-specific pictograms are not required by the standards but are a convention adopted by many, though not all, manufacturers. Some prefer to use their own symbols. The standards do, however, require the “Type”, standard number and date is referenced on garment label.

However, in addition many manufacturers also use the pictograms shown in the table below to indicate the Type of clothing. Note that these Type-specific pictograms are not required by the standards but are a convention adopted by many, though not all, manufacturers. Some prefer to use their own symbols. The standards do, however, require the “Type”, standard number and date is referenced on garment label.

How is Chemical Resistant Clothing Tested?

The process for certification of clothing to these standards includes three types of testing:-

| 1. Tests assessing the physical properties of garment and construction. | Abrasion Resistance Test methods for each are given in separate referenced test standards with the results of each classified as 1 to 6 (6 being the highest). Classifications are defined in tables in the reference standard EN 14325. |

| 2. Tests for resistance of the fabric against either penetration or permeation of liquids or gases. | Resistance to Penetration / Repellency test for Type 6 garment fabric (EN ISO 6530) Assesses the ability of a fabric suspended at 45o to resist penetration of four specific liquids, identifying a percentage for both penetration and repellency and classifying each as 1 to 3 (3 being the highest) with minimum performance requirements. Resistance to Permeation of chemicals for Types, 1,3 and 4 garment fabric (EN ISO 6529) Assesses resistance against permeation of chemicals. The standard for Type 3 and 4 does not define any specific chemicals, but those tested are dictated by the application. The standard also requires at least one test with a minimum class 1 result on a “seams exposed in use”. The Type 1 standard for gases and vapors however specifies 16 chemicals that must be tested on fabric, seam and components such as visor and gloves and with minimum performance requirements. |

| 3. “Type” tests on the whole finished garment. | The testing that defines the difference between the clothing Types is primarily the “Type Test” on the whole garment. The principle for each is the same: –

|